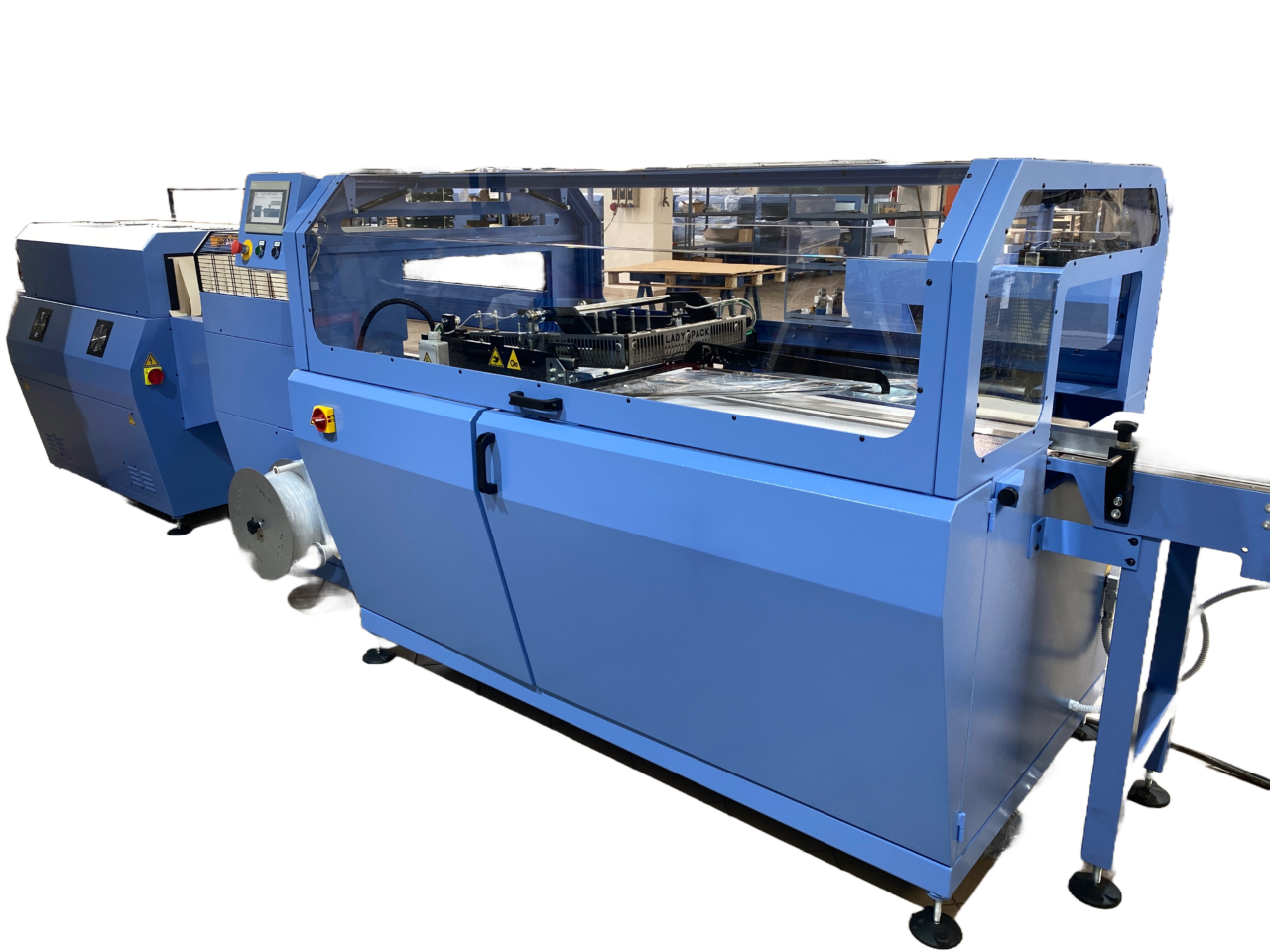

AUTO 60 UNICA with SEPARATE SHRINK TUNNEL

Here is a solution, which combines the performances of an automatic L-sealer, equipped with a monolithic sealing knife and with many devices for high productivity and the performances of a separate, therefore longer and more powerful shrink tunnel.

The result is a packaging line, which meets the requirements of high productivity, fine esthetical shrinkage and limited budget. A compromise, which satisfies everybody! (AUTO 60 UNICA with SEPARATE SHRINK TUNNEL).

The synergy between an automatic angular packaging machine equipped with a monolithic sealing blade and a separate shrinkage tunnel, longer and more powerful than the compact version, constitutes an innovative solution to optimize the industrial packaging process.

The automatic corner packer represents the heart of this solution, offering high performance and superior production efficiency thanks to its ability to pack quickly and precisely. Equipped with a monolithic sealing blade and advanced features, it ensures reliable sealing and an aesthetic presentation of the packaged products. Its integration with a separate, longer and more powerful shrinkage tunnel is a key element to further improve the aesthetic quality of thermoplastic film shrinkage.

This shrinking tunnel, with its length and power characteristics greater than compact ones, allows for more uniform film shrinkage and high aesthetic quality. This results in a more appealing visual appearance for packaged products, ensuring an impression of professionalism and attention to detail.

This intelligent combination of automatic corner packaging machine and separate shrink tunnel offers numerous advantages. The separation of functions allows greater flexibility in adapting the packaging process to different product types and package sizes, without compromising shrinkage quality or packaging speed.

Furthermore, this hybrid solution allows you to maintain a low economic investment, allowing companies to access superior performance without having to make an excessive outlay.

The compromise between production efficiency, aesthetic quality of shrinkage and investment containment is the strong point of this packaging line. It offers the ability to meet high production demands while maintaining superior product presentation while ensuring more sustainable cost management.

In conclusion, this combination of machinery represents an optimal balance between production performance, aesthetic packaging quality and reasonable investment, offering a complete solution that meets the needs of a wide range of industrial sectors.

(AUTO 60 UNICA with SEPARATE SHRINK TUNNEL)

see also Automatic shrink wrapping machines