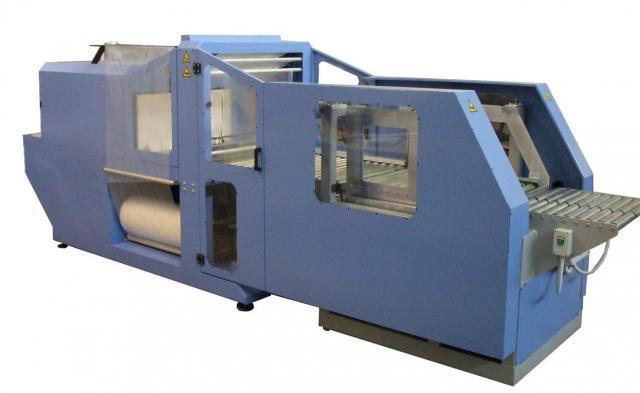

Shrinkwrappers Pactur

The shrinkwrappers are built to pack and protect various medium-large and medium-high weight products with shrink film. Just to name a few examples: bottles, jars, pots and jars, reams of paper, ironing boards, folding ladders, furniture components, wooden planks, metal plates, etc.

They correspond to three types:

1- semi-automatic shrinkwrappers, where the operator manually deposits the product on the work surface or manually composes the multipack on the work surface. Then activates the pusher, by pressing two buttons, to transfer the product to the machine;

2- automatic shrinkwrappers with in-line loading belt, which automatically introduces the bundle into the machine;

3- automatic shrinkwrappers with loader, consisting of a motorized belt placed at 90 ° with respect to the machine. Sensors for product detection and counting, pushers for the composition of the multipack and its transfer to the machine.

But what is the UNIQUE feature of our Shrinkwrappers?

The one that both coils are placed in the low position.

This favors:

– the safety of the operator, who does not have to lift a heavy reel in order to place it in its high housing, but only places them both a few centimeters from the ground

– the speed of the reel change, as a consequence of the above: the operation is immediate, thanks to the functional housing of the film.

The unwinding of the shrink film is fluid, because both reels are equipped with a motorized film unwinder.

The cutting blade consists of a Teflon-coated knife, at a constant temperature.

The shrink tunnel, in the standard version, is equipped with a metal mesh conveyor belt, suitable both for the use of PE (polyethylene) shrink film, and for dragging bulky and heavy products.

A series of optional equipment helps to make Pactur shrinkwrappers even more flexible.

By way of example of the range of options, the following can be listed:

– pressure device, with synchronized descent with the movement of the sealing bar, to stabilize the products during the welding phase;

– mechanical overturning device, to facilitate the passage of irregular products from the loading surface to the tunnel belt;

– lateral sponge rollers, placed at the exit of the tunnel, to lean the edges of the lateral film against the product;

– double belt, to release the sealing times from the retraction times and, therefore, increase productivity.

Moreover, the semi-automatic and automatic shrinkwrappers, like all the other Pactur shrink wrappers, all under the Ladypack brand, are also distinguished by their design, which makes them beautiful, practical, reliable, intelligent, robust, safe and economically very convenient.

First of all, beautiful, because Pactur always gives an unmistakable impression with its personalized design.

They are also practical, because the Pactur shrinkwrappers have been designed and built to make work easier for users, thanks to the peculiar position of both film reels.

Then they are reliable, because they are the result of more than thirty years of experience, dedicated to the production of packaging machines for shrink film.

Finally, they are robust, because the LADYPACK shrinkwrappers have been built with 6 mm thick steel sheets and high quality components.

CUSTOMIZED SHRINKWRAPPERS

On request, Pactur produces customized shrinkwrappers of different sizes, calibrated according to the customer’s needs.

The customized shrinkwrappers are the flagship of our production flexibility that TREAT EVERY CUSTOMER AS A UNIQUE CUSTOMER exactly according to the artisan “tailoring” principle.

The most common CUSTOMIZATIONS are:

Presser connected to the welder, which presses and stabilizes the products during the welding phase

Tilting device under the welder, for the passage of irregular products

Motorized conveyor belt, between welder and tunnel, so that the welding phase and the movement of the tunnel belt are two independent operations, with the aim of greater productivity

Pressing rollers for the film exiting the tunnel, which compress the excess film on the sides of the product

The shrinkwrappers can basically have four types of loading, according to the customer’s needs:

Manual by operator

Automatic with in-line motorized conveyor belt

Automatic with 90 ° motorized conveyor belt and pusher

Automatic, with automatic composition of the multipack.

(PDF) A802 depliant

(PDF) A802 with charger depliant

(PDF) Fardellatrici depliant multilanguage

PACTUR s.r.l.

Headquarter

Via Nannetti, 4 40069 – Zola Predosa

Bologna – Italy