Shrink tunnels

Product Description

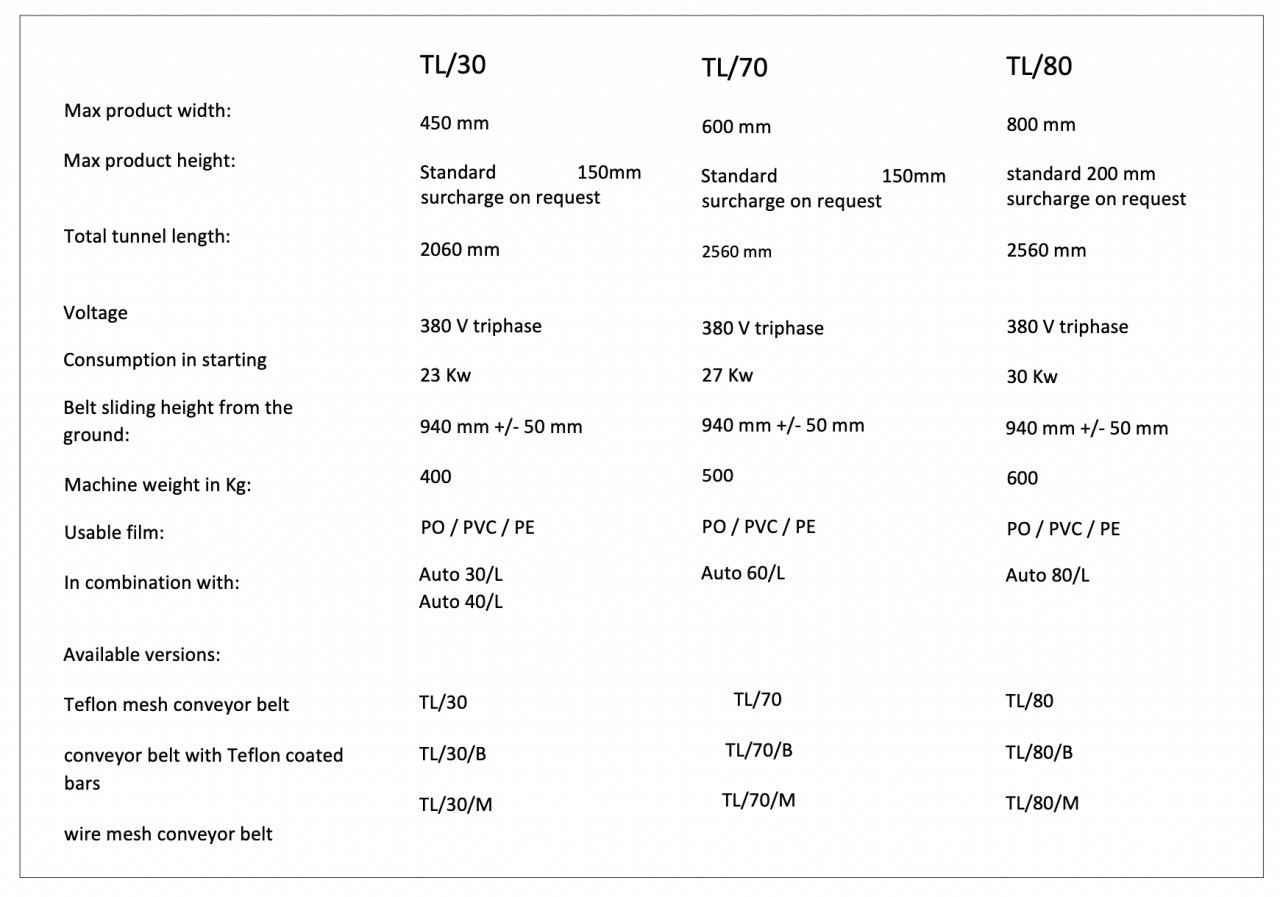

Mod. TL30 – TL70 – TL80

Pactur shrink tunnels are available in different sizes (TL / 30, TL / 70 and TL / 80) according to the the sizes of the products.

Within the range of shrink tunnels, three versions are available for each model:

– Teflon mesh conveyor tunnel;

– Silicon coated rolls;

– Metal mesh conveyor belt.

These versions make the shrinking tunnel suitable to the different kinds of products and of used films.

For example, for light and irregularly shaped products, teflon mesh is suitable. On the other hand, if the products must have a remarkable finishing, with an excellent retraction effect also on the bottom side, the suitable solution is the tunnel with silicon coated rolls.

On the other hand, when the used film is polyethylene, when the products are heavy and the packaging has only protective purposes, the convenient technical answer is the metal mesh tape.

The shrink film reacts to the heating process, by shrinking, which means, that it becomes tight to the product, according to its shape. The shrink films are polyethylene, polyolefin, PVC.

The shrinking process allows to make multipack products tight together. The products are sealed with plastic film (neutral or printed) which adheres perfectly to the product by passing through a special shrink tunnel. Heat shrinking is particularly suitable for food items and other kinds of products (perfumes, displays, etc.), it allows a complete closure of the plastic film, granting, at the same time, protection.

Pactur shrink tunnels are marked by high shrink power and, consequently, high shrink capacity.

This quality result is obtained thanks to the powerful ventilation, which distributes the hot air over the product surface, in a very homogeneous way. Therefore not only the Ladypack shrink tunnels guarantee high performance, but also reliable quality on high performance. These same shrink tunnels are produced both with independent control and with control from the automatic packaging machines, to which they are connected.

In case of independent control, the tunnels are obviously equipped with a panel, for the adjustment of the main functions, such as speed, temperature and air flow. In case of connection to a machine, these functions are controlled by the machine PLC.

ASK NOW FOR A QUOTATION OF OUR SHRINK TUNNELS

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at +39 051 6167287

see also Ladypack.com

Animation

3D photos

Videos

PACTUR s.r.l.

Headquarter

Via Nannetti, 4 40069 – Zola Predosa

Bologna – Italy