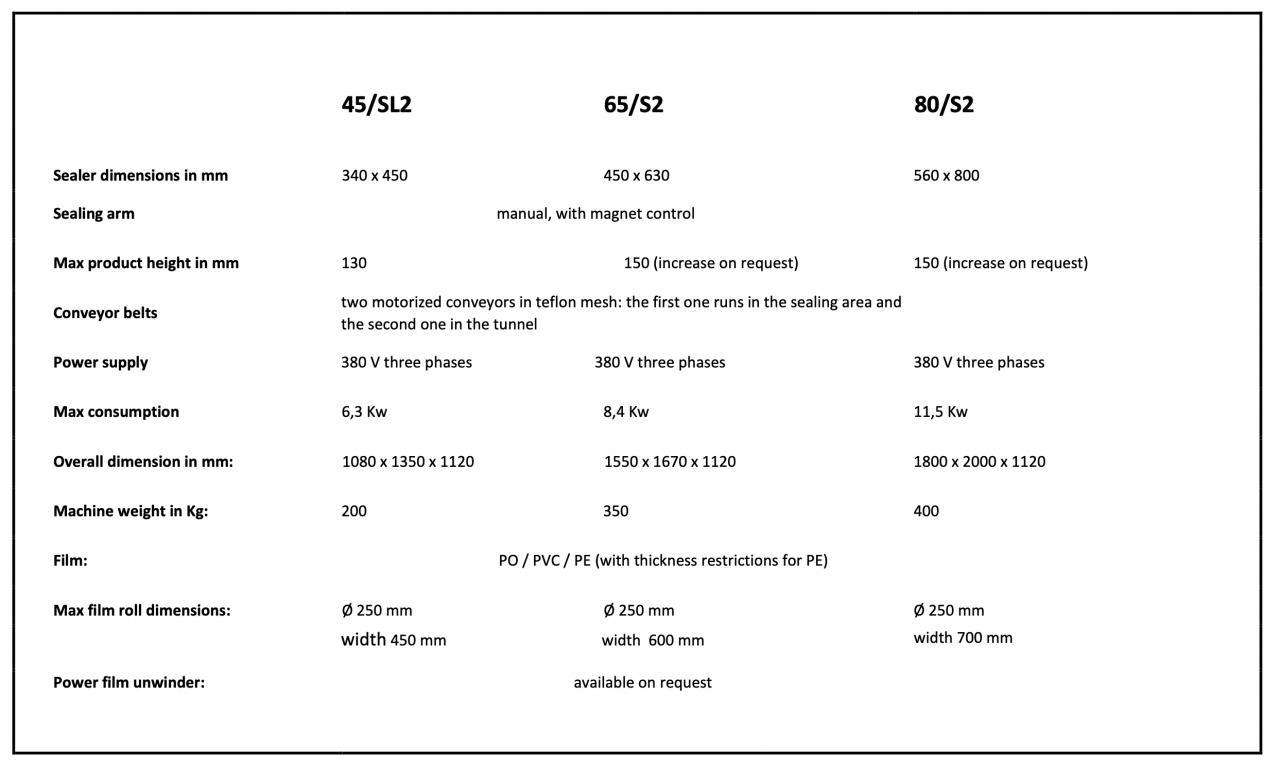

Semiautomatic L-sealer packaging machines with manual sealing arm

Product Description

Mod. 45/SL2 – 65/S2 – 80/S2

Performing, user friendly Semiautomatic L-sealer packaging machines with manual sealing arm, at a very competitive price. The shrink tunnel is at 90 ° from the product flow direction.

Sealing arm available both in manual version with magnet control and in semiautomatic version, with piston control.

There are three pneumatic piston controls on the machine: buttons, pedal and timer.

Equipped with two Teflon mesh conveyor belts, with independent control: the first belt automatically transports the product to the second belt, after the sealing operation, whereas the second belt runs inside the shrink tunnel.

Thus, the welding and heat-shrinking operations are independent and productivity is increased.

As soon as the product is welded, it goes onto the second belt and enters the shrink tunnel, so that the operator can immediately load the next product.

Possible use of the machine as a welding machine only, without shrinking.

Possible setting of the multiple work cycle, for greater speed: only after a set number of packs, the first conveyor belt is activated for the transport of the different bags welded to the second belt.

The shrink tunnel is configured at 90 ° from the direction of product flow.

All manual and semi-automatic L-sealer packaging machines are equipped with an electronic system that automatically controls and corrects the sealing time (intelligent sealing system).

Furthermore, the manual and semiautomatic packaging machines are equipped with an automatic cycle which gives the possibility of packaging a product and having it back to the operator, who picks it up.

The product can get back to the operator or exit from the opposite side.

The machines are available with shrink tunnel in three versions:

– shrink tunnel with teflon mesh conveyor belt

– tunnel with metal net conveyor belt

– and finally with silicone-coated rods

The LADYPACK economic semi-automatic angular packaging machines with manual welding arm have limited foot print and are equipped with a real shrink tunnel that grants high packaging rates and excellent results. Read also about Semi-automatic Linear Packaging Machines.

All machines are manufactured entirely in Bologna in Pactur headquarters.

ASK NOW FOR AN OFFER OF OUR SEMIAUTOMATIC L-SEALER PACKAGING MACHINES

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at +39 051 6167287

see also Ladypack.com

Optionals

- Maggiorazione cappa del tunnel per passaggio di prodotti più alti di 150 mm

- Piano di rialzo, collocato sotto al nastro trasportatore, in area di saldatura, per sollevare il livello d’appoggio di prodotti molto bassi

- Rullino metallico fissato fra il primo e il secondo nastro trasportatore, per il passaggio di prodotti corti o irregolari (disponibile solo sui modelli a due nastri)

- Gruppo svolgifilm motorizzato, per agevolare l’operatore nella svolgitura manuale del film (optional consigliato per il modello 80; dotazione di serie per il modello 110)

Animation

3D photos

Videos

PACTUR s.r.l.

Headquarter

Via Nannetti, 4 40069 – Zola Predosa

Bologna – Italy