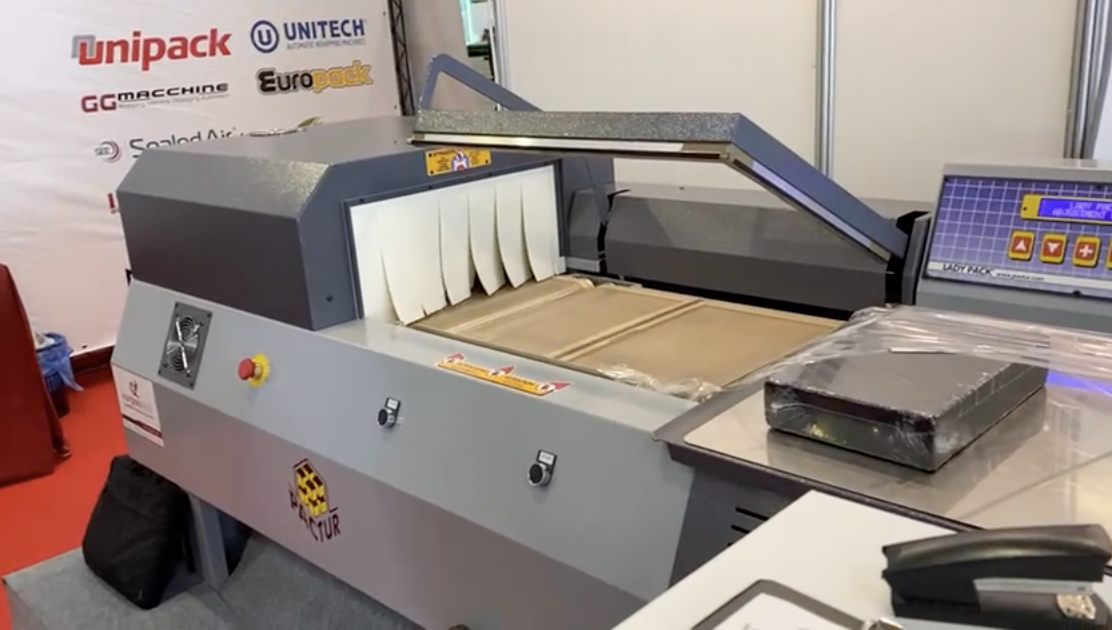

Here is a customized version of our automatic continuous side seal machine Auto 60/L: parallel conveyors, which keep the product compact, and side dryers, instead of the shrink tunnel.

see also www.pactur.com

Here is a customized version of our automatic continuous side seal machine Auto 60/L: parallel conveyors, which keep the product compact, and side dryers, instead of the shrink tunnel.

see also www.pactur.com

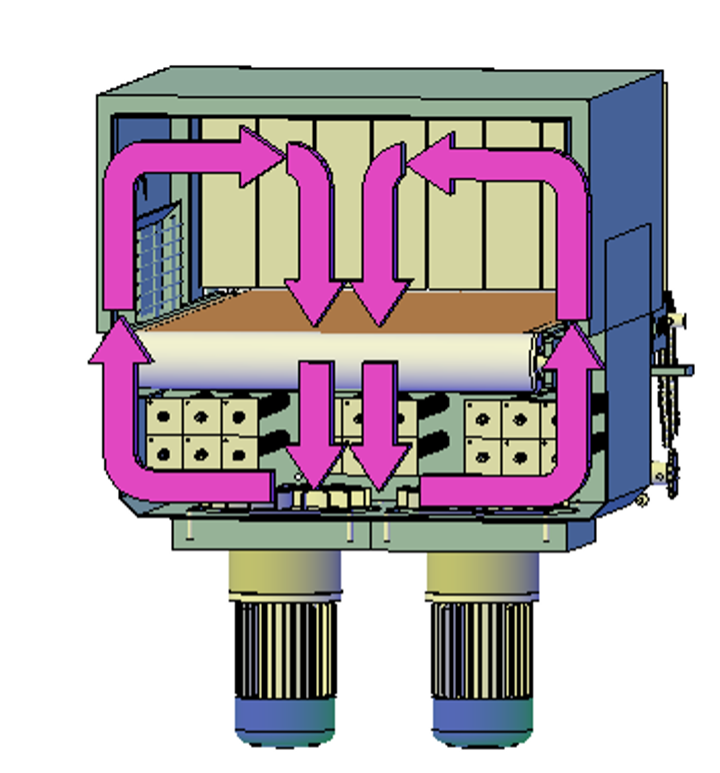

Pactur’s shrink tunnels are designed so as not to lose the heated air into the atmosphere, thanks to a system of turbines developed by us to create an internal recirculation of the air and, at the same time, to blow air all over the product.

Temperature control is made through a PID system (proportional-derivative-integrative), which activates solid-state relays. The PID controller is a control algorithm with a predefined structure, which is tuned (calibrated) by choosing the value of some parameters. Correction factors are calculated by comparing the output value with the set value and applying gains that minimize overshoot and oscillation, while implementing the change as quickly as possible. PID control on a shrink tunnel heating system grants a constant and continuous variation of the output within a feedback mechanism of the control loop, in order to verify the process and ensure the absence of oscillations and, therefore, maximum saving.

Wholly automatic machines for packing fruit and vegetables.

AUTO 40/L automatic continuous sealer fruit and vegetable packaging machines dedicated to the specific packaging of dates.

Dates are a type of staple food for people in Middle Eastern countries. Some consider it a sacred fruit and it is almost always served to guests as part of each house’s hospitality path. Spanish missionaries brought the tree to the New World in the 18th and early 19th centuries. Date palms are grown in the Canary Islands, North Africa, the Middle East, Pakistan, India, Mexico and the US state of California.

Dates can be eaten fresh as they are picked from palm trees, or they can be dried and stored for years.

And now some photos and a video of wholly automatic machines for packing fruit and vegetables. Good vision!

The Shrink tunnels produced by Pactur are available in different sizes (TL/30, TL/70 and TL/80); the choice depends on the size of the products, which must be shrink wrapped.

Within the range of shrink tunnels, there are three available versions for each model:

– teflon mesh conveyor belt

– conveyor made of silicon coated metal bars;

– metal mesh conveyor belt.

These different versions allow the shrink tunnel to fit various product and various kinds of film.

The advantages of heat-shrink packaging do not end with aesthetics: the main features of the transparent, shrink film are high mechanical strength, good transparency and affordable costs.

For example, for light and irregularly shaped products, teflon mesh belt is suitable. On the other hand, if the result of the the finished, packed product must be aesthetically remarkable, with a perfect shrinkage also on the bottom of the product, the most convenient solution is the tunnel with silicon coated bar belt.

On the other hand, when the used film is polyethylene, when products are heavy and packaging has only a protection purposes, the suitable technical answer is the metal mesh belt version.

The shrink film reacts to high temperature, which reduces about 50% of its initial size, by getting tight to the wrapped product. After cooling, the film retains its new shape.

This process allows the packaging of single, as well as multiple products. Products are sealed in plastic film (neutral or printed) bags, which, after shrinkage, adhere to the product, thus following its shape . Thermo-shrinking is particularly suitable both for food items and for other kinds of products (graphical, cosmetic, pharmaceutical products, etc.), it allows a complete closure of the plastic film, guaranteeing protection from external agents and unwanted openings of the packages.

A limitation of the shrink wrap is that, once opened, the bag is no longer resealable and reusable, because the film is broken. This limit becomes an advantage if we read it as a guarantee of the inviolability of the product: intact film = inviolate product.

The shrink tunnels are entirely produced by Pactur.

Pactur heat-shrinking tunnels are very powerful, which grants high shrink quality and capacity.

This quality result is achievable thanks to the powerful ventilation, which spreads the hot air all over the product surface very homogeneously.

These heat-shrinking tunnels are produced both with independent control and with control from the automatic packaging machine PLS.

In the case of independent control, they are obviously equipped with a control panel for the adjustment of the three main functions: temperature, conveyor speed and ventilation speed. Whereas, in case of control from the machine, its functions are adjustable from the machine touch screen, where they can also be memorized.

Packaging machines for parquet boards

Parquet is one of the most popular home floors in Italy and abroad, and also one of the most beloved. A room with parquet is warm, elegant and refined, because wood gives every room a comfortable and classy look. Furthermore, no floor looks like the other, because the wood characteristics vary from board to board, and can be mixed in ever new and pleasant geometries, making the customization opportunities almost infinite.

The widespread use of parquet in the building field is in fact due to the beauty and versatility of wood: just think about how many types of wood there are on the market and how much the appearance of a room can change depending on the choice of the parquet. .

For the floating installation, pre-finished boards are used, with cut edges to create the classic male-female attachment, a sort of joint like a puzzle. They are installed on an existing floor, after using a mat of insulating material to level the support surface.

The first advantage is immediately evident: thanks to the interlocking mechanism, no nails or glues are required for installation. This means that this type of installation is not only economical, but also eco-sustainable: without the use of artificial adhesives, in fact, the environment and the quality of the air inside your home are better respected. The second advantage is the speed and simplicity of the installation itself: floating parquet boards can be positioned in short time and without difficulties. Hence the economic advantage: without manpower and solid wood, the price of your parquet will drop significantly.

Our automatic continuous side seal packaging machines for shrink film are suitable for almost all shapes of parquet boards. Four models are available in our range, with different widths, in order to pack almost any kind of wooden board: from the profiles to a 850 mm wide axis.

Thanks to the side rotary sealer, our machines pack any length of product, therefore they can package boards from the shortest to the longest size, even with a length of several meters.

Moreover, they use both Polyolefin (PO) and Polyethylene (PE) films, therefore they meet any requirement, both for an aesthetic package and for a strong, tough protection package.

Here is a video, showing one of the continuous side sealer models, Auto 60/L, in operation.

Pactur strongly recommends constant sealing blade maintenance: if the sealing parts of your packaging machine are kept in excellent condition, this goes to the full advantage of the quality of the sealing and the performance of the machine.

In fact, if the cutting blade is clean, intact, free of encrusted film residues, without dents or distortions, which alter its linearity, the welding is certainly excellent sealing, with an aesthetically thin line, but very resistant and the times of welding are reduced to the bare minimum.

The same can be said for the welding contrast, composed of rubber and adhesive Teflon: the newer these materials are, with no grooves due to wear, the more effective their beating function against the sealing blade is, to the benefit of both the quality of the cutting and welding, as well as welding times.

Whether you have a manual, semi-automatic or automatic model, the maintenance principle of the sealing block is the same and the resulting advantages are the same.

We are at your disposal to identify the details suitable for your packaging machine.

You just have to tell us the serial number of your machine and, if you can, send us some pictures of the welder and the contrast, so that we can examine their condition.

We will identify with you the parts, which need to be replaced for the correct sealing blade maintenance.

Constant and careful maintenance of the welder will pay off with excellent performance of your packaging machine.

see also RICAMBI PACTUR e LADYPACK

Here are the Pactur machines presented in the Exhibition PRINT & SIGN in Bucharest, a fair dedicated to graphics, held in these days, where I went personally and during which I was able to interview the Sales Director of KangooPack, Mr Daniel Cotop, and pass days of work and rare moments of relaxation with the entire staff.

Tomorrow we return to PACTUR in Bologna, in the heart of the Packaging Valley where our company is based.

In the meantime, I have prepared a short video that I hope you like it. (see also www.pactur.it).

The prestigious company Rizzoli Emanuelli, our client, has allowed us to enter its production site and to make these shots. First, therefore, let us express our gratitude.

Let’s see our Automatic Shrink Wrapper A802 with side pusher in operation.

We are pleased to highlight some particularities of the packaging machine:

The low position of both reels, which facilitates the safe film change

A system of rollers and film-opener ties brings a flap of film at the top, so that operation returns to the traditional one, with a flap of film descending from above and one rising from below

This dragging of a layer of the film at the top does not affect the fluidity of the work and the sliding of the film itself

The side loader is suitable for different product formats

The double metal mesh conveyor belt in the welding area and in the tunnel makes the two operations independent, therefore the retraction is not affected by the welding times

As for the aesthetics and robustness of the Automatic Shrink Wrapper A802, we leave the judgment to you.

vedi anche Rizzoli Emanuelli

Pactur is responsive to the customer’s needs.

Here is another example of Pactur’s flexibility, who is able to satisfy customers’ requests with enthusiasm and to appreciate the final result: the chamber machine KLOK 550 in an usual and very original black version.

see also LadyPack

A complete and transversal range of offers for the entire mass market and durable consumer goods industries at FIERA MILANO RHO – IPACK-IMA 2022- ITALY 3-6 MAY.

It is a system exhibition that tells each phase of the supply chain: from processing to packaging, from design to innovative materials, from labeling to the end of the line, from automation to digitization.

With over 74,000 visitors, IPACK-IMA 2022 is the reference international event for market operators and a privileged meeting point for buyers from the food and non-food sector. An unmissable event in Milan, which will mark the real restart for all the sectors represented.

This year I present a model for every type of shrink wrapping machines, from manual to semi-automatic and automatic angular up to automatic ones with linear welder.

IPACK-IMA 2022 – FIERA MILANO RHO – ITALY 3-6 MAY

IPACK-IMA 2021https://www.pactur.com/2020/01/09/premio-mascagni/

PACTUR s.r.l.

Headquarter

Via Nannetti, 4 40069 – Zola Predosa

Bologna – Italy